hardness test standards|is 1500 part 1 pdf : inc Metallic materials — Rockwell hardness test — . International Standard 6508-1 was prepared by the Technical Committee ISO/TC 164, Mechanical testing of metals, Subcommittee SC 3, Hardness testing. This first edition of ISO 6508-1 cancels and replaces ISO 6508:1986 and ISO 1024:1989, of which it constitutes a . 1080p. Branquinha Magrinha Gostosa Gemendo no Pau Grande do Namorado! (Gabbie Luna) 7 min Gabbie Luna Official - 11.6M Views - 1080p. Sexo gostoso com a minha .

{plog:ftitle_list}

Sobre a Jadlog Produtos e Serviços Unidades e Franquias T.

Listed below are common American Society for Testing and Materials (ASTM) standards that reference hardness testing. Newage Testing Instruments recommends that you obtain a copy of the appropriate standard for your application and that you read and . There are various standards available for the different hardness testing methods. Generally, the internationally accepted standards for hardness testing are those issued by ASTM (American Society for Testing Materials) .

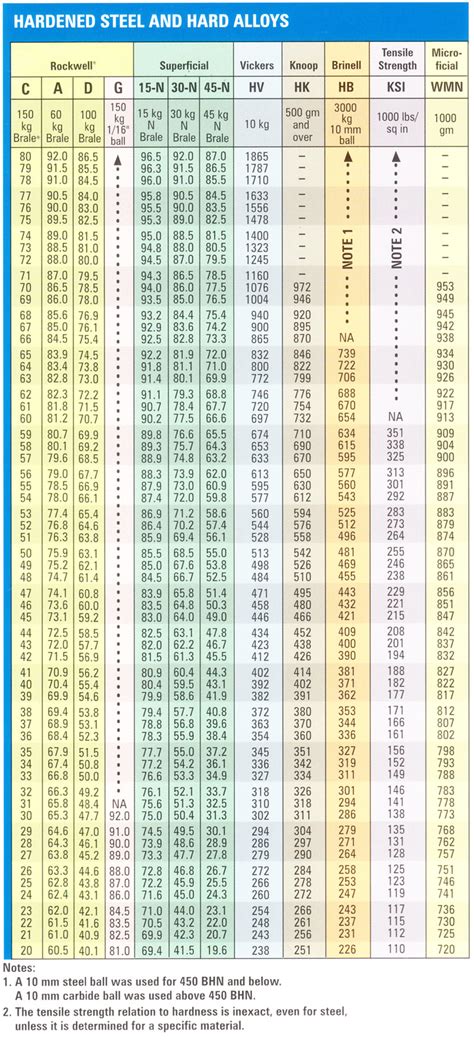

The main governing standard for Rockwell Hardness Testing is ASTM E18. Table 1: Brinell vs Rockwell Hardness Test 12. Brinell, Rockwell, and Vickers Hardness Conversion Table. The approximate conversion of Brinell, Rockwell .

Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Learn more about hardness testing basics here. The Rockwell hardness test method, as .Metallic materials — Rockwell hardness test — . International Standard 6508-1 was prepared by the Technical Committee ISO/TC 164, Mechanical testing of metals, Subcommittee SC 3, Hardness testing. This first edition of ISO 6508-1 cancels and replaces ISO 6508:1986 and ISO 1024:1989, of which it constitutes a .

Hardness testing standards have been set by various organisations such as The American Society for Testing and Materials (ASTM) and The International Organisation for Standardisation (ISO), prescribing specific varieties of a hardness test determined by factors such as the type of indenter, applied force, and procedure of force application. . 5.3 Because microindentation hardness tests will reveal hardness variations that commonly exist within most materials, a single test value may not be representative of the bulk hardness. Vickers tests at 1000 gf can be utilized for determination of the bulk hardness, but, as for any hardness test, it is recommended that a number of indents are made and the average .

rockwell hardness testing chart

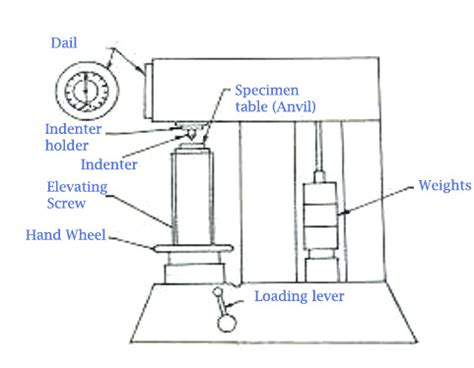

A Rockwell hardness tester. The Rockwell scale is a hardness scale based on indentation hardness of a material. The Rockwell test measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor load). [1] There are different scales, denoted by a single letter, that use different loads or indenters.

1.5 Units— At the time the Rockwell hardness test was developed, the force levels were specified in units of kilograms-force (kgf) and the indenter ball diameters were specified in units of inches (in.). This standard specifies the units of force and length in the International System of Units (SI); that is, force in Newtons (N) and length in millimeters (mm). NIST Rockwell SRMs are transfer standards intended for use in the calibration and verification of the performance of hardness equipment using the Rockwell C and N Hardness Scales (HRC and HRN). NIST Microindentation Hardness SRMs are for use in calibrating and checking the performance of microhardness testers using the Knoop and .

It is applied to the specimen with a test force (to standard from 1 kg to 3000 kg) and held according to the holding time. To calculate the Brinell hardness, two perpendicular diameters of the test indentation are measured on the specimen surface. In addition, the test force N and the diameter of the spherical indenter are required.

Method A is based on the increase in tensile stress during load application. In the linear elastic part of the tensile test, that is at the very beginning of the test, the rate of stress application must be between 1.15 and 11.5 MPa/sec (this corresponds to 10000 and 100000 psi/min).; However, it is clearly stated in ASTM E8 and ASTM E8M that these specifications and method do not .

rockwell hardness tester diagram

1.3 The portable hardness testers covered by this test method are verified only by the indirect verification method. Although the portable hardness testers are designed to employ the same test conditions as those defined in the standard test methods, the forces applied by the portable Rockwell and Brinell testers and the depth measuring systems of the portable .

Standard Test Method for Rubber Property—Durometer Hardness D2240-15R21 ASTM|D2240-15R21|en-US Standard Test Method for Rubber Property—Durometer Hardness Standard D2240 Standard Test Method for Rubber Property—Durometer Hardness> new BOS Vol. 09.01 Committee D11 $ 76.00 In stockThe hardness of rubber and elastomers according to Shore is determined using test procedures standardized in compliance with ISO 48-4 or ASTM D2240.. In the Shore hardness test, the indentation depth is measured using a spring-loaded indenter made of hardened steel to indent the material/specimen.The indentation depth is a measurement for Shore hardness, that is .

ASTM E384: This standard is for hardness testing on a micro-scale, and therefore includes the Vickers and Knoop hardness tests. ISO 6506: This standard mirrors ASTM E10, as it contains the standard method for measuring the Brinell hardness of metals.Institute (NMI) for hardness, and as such, is responsible for traceability in hardness measurements. Objective Impact and Customers • Hardness is the most commonly used industrial test for quality control and acceptance testing of metals and metallic products. • Of over 12 000 ASTM standards, hardness test method standards are

The Brinell hardness number is designated by the most commonly used test standards (ASTM E10-14[2] and ISO 6506–1:2005) as HBW (H from hardness, B from brinell and W from the material of the indenter, tungsten (wolfram) . Durometer is a standard in industry for measuring the hardness (or indirectly, modulus) of a material . Brinell test and the Vickers hardness test. This article will provide an introduction into durometer hardness and the .

In this revision the requirement of method for Rockwell superficial hardness test, calibration of standardized blocks and verification of Rockwell hardness testing machines have been included. In the preparation of this standard, assistance has been drawn from ASTM E 18 -97a ‘Standard test methods for Rockwell hardness and RockwellA Vickers hardness tester. The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. [1] The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter .Standardization of Brinell Hardness Test Blocks Annex A4 1.3 This standard includes nonmandatory information in an appendix which relates to the Brinell hardness test: Table of Brinell Hardness Numbers Appendix X1 Examples of Procedures for Determining Brinell Hardness Uncertainty Appendix X2 1.4 At the time the Brinell hardness test was .Methods of hardness testing and mechanical property tests for base metals are covered by ASTM standards or the individ- . Committee on Standard Methods for Mechanical Testing of Welds, American Welding Society, 8669 NW 36 St, Miami, FL .

is 1500 part 1 pdf

I. Significance of Vickers Hardness Standard Test. Vickers hardness test is the nondestructive testing method, which is significant while evaluating materials, a quality check of the manufacturing procedure, and creating new products. Vickers hardness testing method is the only procedure that we can say is universal because of its scaling, as it can be used for .The ISO 898-1, ISO 3506-1 and ASTM F606 standards describe tests on threaded fasteners (bolts, screws and studs) including steel screws and their mechanical and physical properties such as tensile strength, offset yield (minimum stress), elongation after fracture and hardness.. ISO 898-1 establishes the mechanical properties of fasteners made of carbon steel and alloy .

The Vickers hardness test is suitable for a wide range of applications, including micro hardness testing. On this page, you can find a description of the Vickers hardness test, practical information on how to apply it and a list of our micro hardness testing machines for Vickers. The Vickers hardness test at a glance: Ideal for micro hardness .If a testing machine is also to be used for other methods of hardness testing, it shall be verified independently for each method. This part of ISO 6508 is applicable to portable hardness testing machines. 2 Normative references The following referenced documents are indispensable for the application of this document. For dated See various standards and test specifications for details. Fig. 1-21 Application of similarity principle. Selection Table of Brinell Hardness Test P/D 2. Material type: . Hardness test characteristics. ① The stress state is very soft (α>2), which is widely applicable; In the American metal material standards, a prominent feature regarding hardness testing is the preference for the Rockwell hardness test, supplemented by the Brinell hardness test, and seldom using the Vickers hardness test. The American view is that the Vickers hardness test should mainly be used for metal research and testing of thin, small .

iphone 7 case 10ft drop tested

iphone 7 case drop tests

How to Deposit Money on Parimatch. To make a deposit and .

hardness test standards|is 1500 part 1 pdf